Potato Bags and Agave Straws: Can Producing More Plastic Help End Plastic Pollution?

Bioplastics, materials made from renewable resources, can be an alternative to traditional plastic and offer a solution to plastic pollution.

Reading Time: 4 minutes

Crunch! You just finished your last chip, and now you’re looking around for a trash can. To your dismay, none are in sight. Thankfully, you remember that you don’t need one—you can eat the bag too. That is the promise of bioplastics, a burgeoning solution to plastic pollution made from food waste, bacteria, and even potato starch.

To understand the significance of these materials, we must examine their properties. While all plastics are degradable, they do not return to nature as organic molecules unless they are biodegradable; instead, they break down into tiny, harmful fragments known as microplastics. In contrast, biodegradable plastics do not require chemical or physical processes to decompose and are broken down by microorganisms such as bacteria and fungi. Biodegradable bioplastics are made from either polylactic acid (PLA) found in crops or polyhydroxyalkanoates (PHA) found in microorganisms.

PLA is made through the fermentation of lactic acid found in organic compounds and forms thermoplastics—plastic polymer materials that can be continually melted and reshaped—similar to polyethylene terephthalate and polypropylene. Its ability to crystallize creates a variety of uses in biomedicine, 3D printing, and packaging. Since PLA is composed of lactic acid and starches, it is biodegradable under anaerobic digestion and high temperatures of around 140 degrees Fahrenheit, returning to nature as non-toxic products such as carbon dioxide and water.

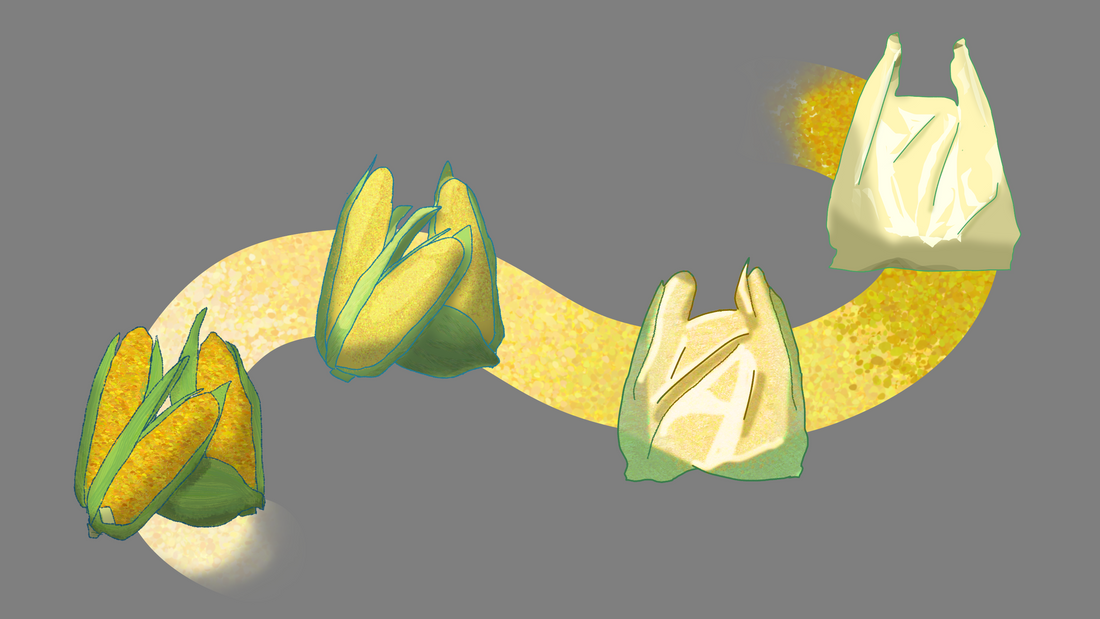

PHA is synthesized from food waste by microorganisms, such as bacteria and archaea. These microbes are cultured in environments that have nutrient-limiting concentrations of nitrogen, phosphorus, sulfur, and oxygen but have extremely high levels of carbon found in animal and plant oils. The microbes ferment the carbon sources—sugar or lipids—to form intracellular carbon reserves, which are PHA monomers. PHA is biodegradable through the same microbes, which excrete PHA depolymerase enzymes that break PHA into water-soluble molecules. The degradation process occurs with exposure to soil, compost, or marine sediment.

Beyond sustainability, bioplastics can reshape the future of our planet. Every year, a large majority of plastic waste is generated. Over 86 percent of plastics end up in landfills instead of recycled. As plastic waste builds up, the production and disposal of these commodities often leave their mark on air and water pollution, creating major environmental issues. Traditional plastic is made from petroleum and natural gases, which burn fossil fuels and release a total of 1.8 billion tons of greenhouse gases annually, exacerbating the issue of climate change and raising temperatures around the world. Plastic also finds its way into animals through consumption; for example, an estimated 90 percent of seabirds contain debris in their bodies. Since plastic has low reactivity to environmental factors, it only further breaks into microplastics, which carry toxic chemicals such as Bisphenol A (BPA)—a known carcinogen and poison that increases chances of diabetes and heart disease. These microplastics make their way through the food chain, affecting over 800 marine species as well as humans.

In stark contrast, bioplastic production does not require burning fossil fuels, making its greenhouse gas emissions significantly lower. For one metric ton of bioplastics produced, there are 0.828 metric tons of carbon dioxide produced, whereas for one metric ton of traditional plastic produced, there are 2.4 metric tons of carbon dioxide produced. With just corn-based PLA, an estimated 25 percent of U.S. industrial greenhouse gas emissions would be cut. Instead of traditional plastic, which fractures into microplastics, biodegradable bioplastics can fully return to nature as carbon dioxide, water, and other organic compounds. Furthermore, bioplastics such as PHA have the potential to reduce food waste by using microbes to convert leftover vegetable oils to PHA.

As countries implement policies to produce sustainable materials, the bioplastic industry only continues to gain traction, with an estimated market size of $44.7 billion by 2030. The field of bio-based materials has become interdisciplinary as businesses and industries are forced to meet consumer interests for sustainable products in packaging and more. Leftover fibers from tequila production, called bagasse, are dried and molded into agave straws for drinking. In a collaboration with Gdańsk University of Technology, Bio Plast Pom created NOPLA, a material derived from potato starch capable of degrading in household composters and can be produced in traditional thermoplastic factories. NotPla, a business company focused on sustainable packaging, created seaweed and plant packaging for biodegradable food containers. The list goes on, and research for the extent of these materials continues to grow. The Massachusetts Institute of Technology (MIT) and Binghamton University are working on creating bio-based cleansers and recycling food waste, respectively.

Such interest in bioplastics begs the question: “Why haven’t we stopped plastic pollution yet?” Well, the case of bioplastics is more complicated. Some bioplastics, such as PLA, although listed as biodegradable, require specific conditions such as high industrial temperatures to biodegrade. If not properly disposed of, bioplastics will end up sitting in landfills just like their traditional counterparts. While bioplastics don’t produce greenhouse gases, they result in more pollutants since they use pesticides and fertilizers in order to convert organic materials to plastics, many of which are toxic or carcinogenic to humans and animals. Economically, bioplastic production is also currently unfavorable, since the materials needed to produce strong bioplastic are expensive and often compete for crops grown for food.

The solution of bioplastics is not without faults. While it seems that the cons currently outweigh the pros, scientists have not given up on these green materials. Researchers at Virginia Tech and MIT are testing new biopolymer combinations for better biodegradability and tuning properties such as mechanical strength and water resistance to create more practical applications. They have conducted studies to incorporate nanomaterials into food packaging bioplastics to improve functionality and degradation rate. Bioplastics have already been implemented in markets around the world and will continue to grow more viable as research continues. Bioplastics are not just part of a consumer desire to greenwash markets; they are one step closer to reducing our environmental footprint and using sustainable materials that do not harm our planet.